Connected manufacturing systems for planning, control, and profitability

Manufacturing operations require precision, coordination, and visibility across production, inventory, quality, and finance. At Junious Digital Labs, we implement Odoo as a unified manufacturing system that helps businesses plan efficiently, control costs, and scale production without operational chaos.

Odoo brings manufacturing, inventory, quality, maintenance, and financial control into one connected platform.

Why Manufacturers Choose Odoo with JDL

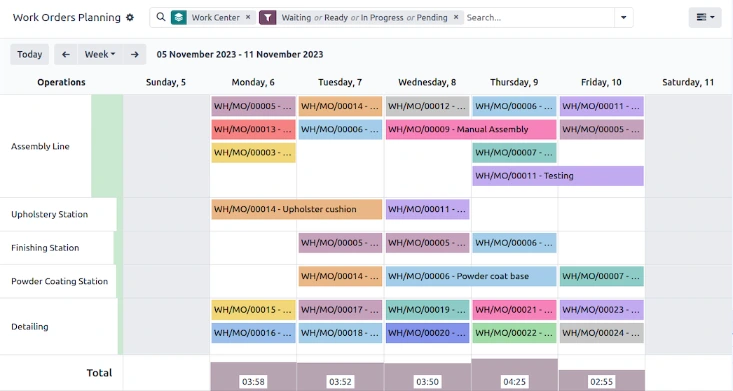

Shorter production lead times

Odoo connects planning, production, and inventory in real time. This allows teams to coordinate better, respond faster to changes, and reduce delays across the production cycle.

.

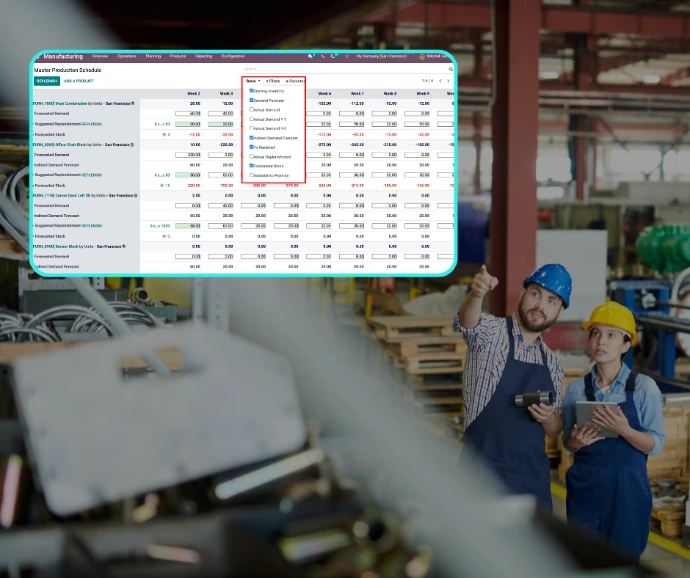

Lower inventory levels

Improve demand planning and stock forecasting to reduce excess inventory, minimize waste, and lower carrying costs while maintaining production continuity.

Better pricing and margin control

Track production costs accurately and understand true product margins. Odoo helps identify cost drivers and supports smarter pricing and production strategies.

Higher productivity

Automated workflows, integrated systems, and real-time reporting reduce manual work and improve decision-making across the shop floor and management teams.

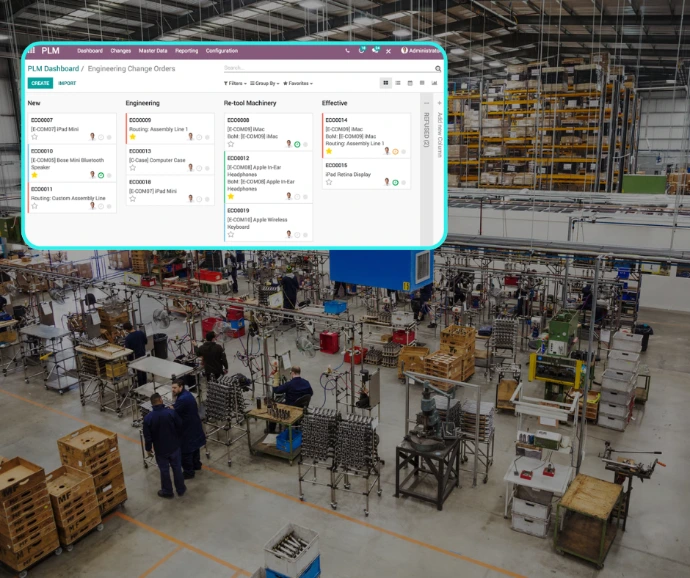

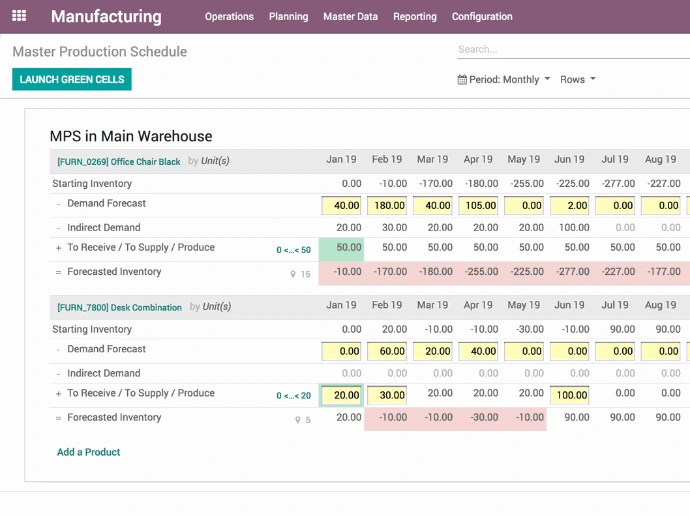

Integrated Supply Chain Planning for Manufacturing

End-to-end product lifecycle visibility

Maintain transparency across every production stage. Identify bottlenecks, delays, or inefficiencies early and take corrective action before they impact delivery.

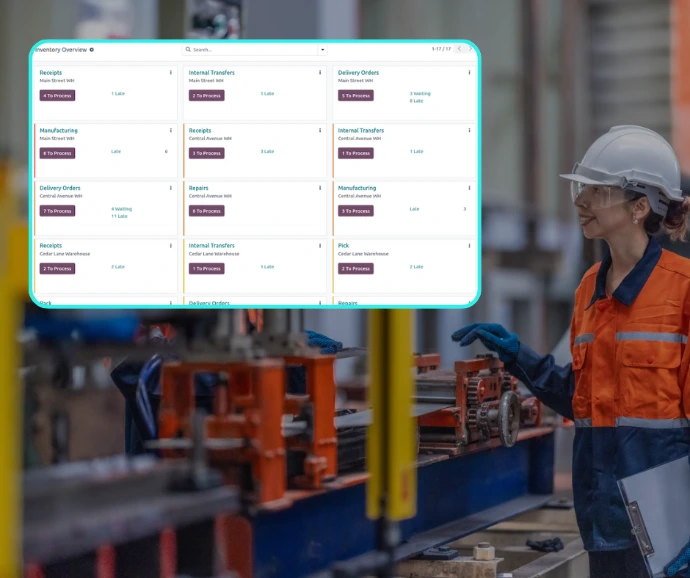

Real-time inventory visibility

Track raw materials, work in progress, and finished goods across warehouses and locations. Monitor stock movements and ensure materials are available when needed.

Vendor and supplier collaboration

Stay connected with suppliers through real time order updates, delivery tracking, and automated alerts for changes or delays.

Demand forecasting and planning

Analyze historical data, trends, and customer behavior to forecast demand accurately and align production plans accordingly.

Margin Analysis and Cost Control

Track production costs accurately

Monitor costs related to materials, labor, overhead, and equipment usage across production orders.

Analyze product margins

Understand profitability at the product level by comparing costs and revenues over time.

Identify cost drivers

Capture cost data at every production stage to pinpoint inefficiencies and optimization opportunities.

Monitor profitability trends

Track financial performance over time to guide strategic planning and continuous improvement.Financial Control for Manufacturing Businesses

Production level financial reporting

Analyze performance by production line, product, department, or business unit.

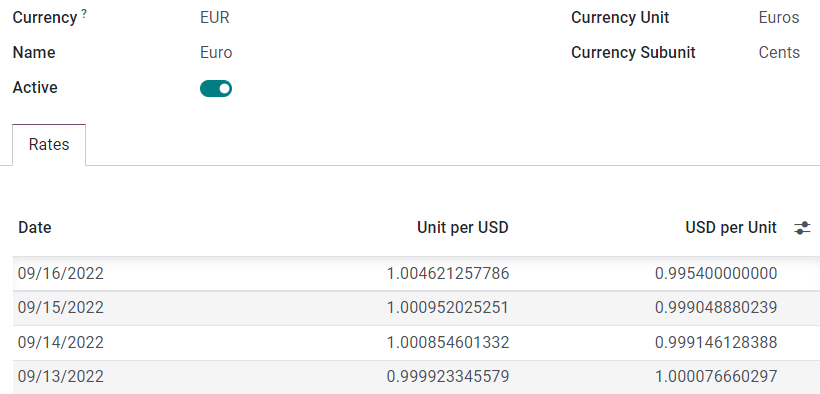

Multi-currency cash management

Support international operations with accurate currency handling and reconciliation.

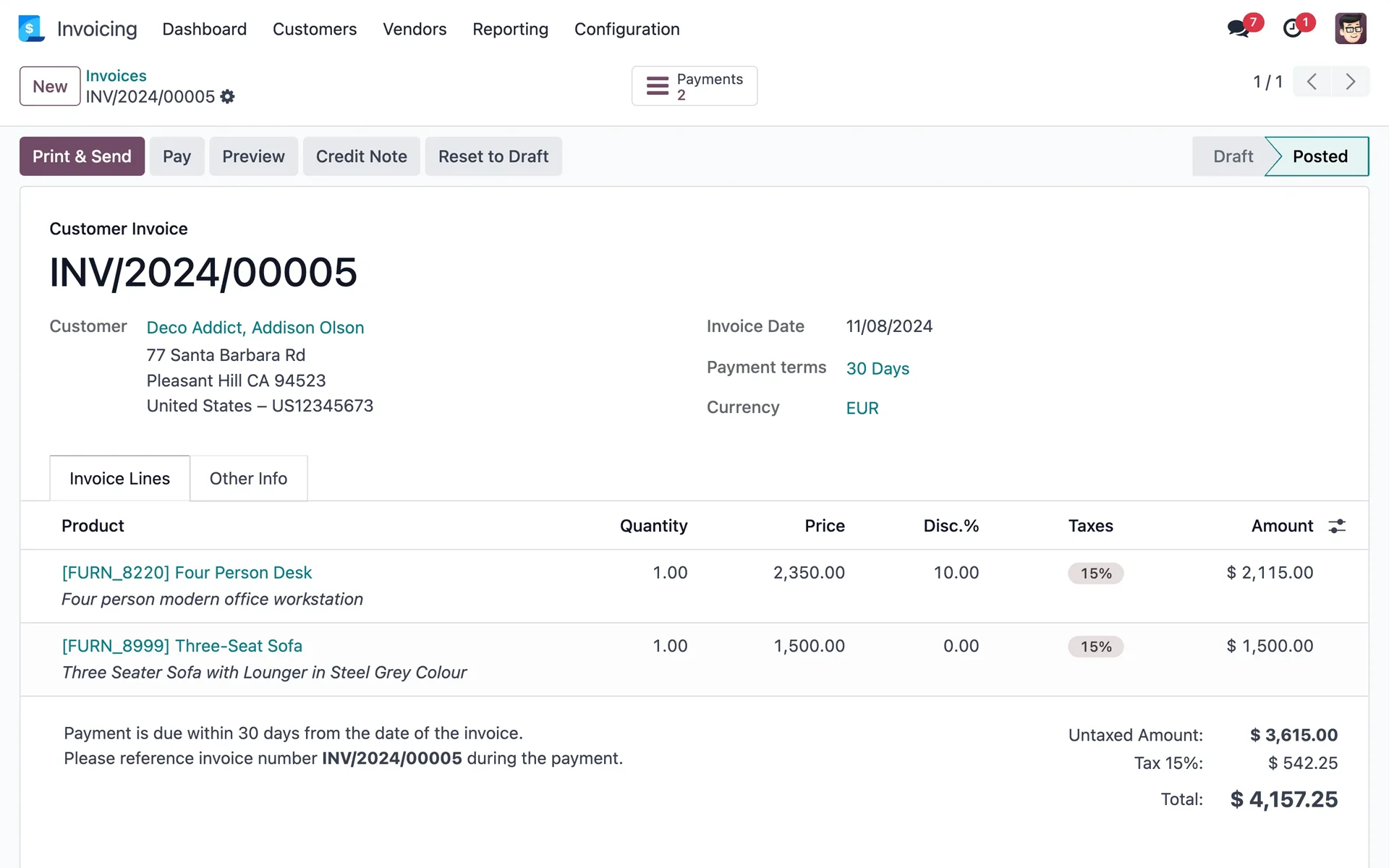

Invoicing and tax management

Handle invoicing, accounts receivable, VAT, expenses, and assets in one accounting system.

Real-time reporting

Access up-to-date financial and operational data to guide decisions and protect margins.

OUR APPROACH

We do not just implement manufacturing software.

We design connected manufacturing systems.

Our approach focuses on operational clarity, automation, and long term scalability so manufacturers can produce efficiently, control costs, and grow without increasing complexity.